India’s auto components industry is accelerating at an unprecedented pace, positioning the country as a global powerhouse in automotive manufacturing and innovation. With a robust growth trajectory, increasing export potential, and a strong push towards electric vehicles (EVs), the sector is set to play a pivotal role in India’s economic landscape. According to the Automotive Component Manufacturers Association of India (ACMA), the industry achieved a record turnover of $74.1 billion in FY24 and is projected to reach $200 billion by FY26. Here’s an in-depth look at the key trends, growth drivers, and opportunities shaping this dynamic industry as of February 2025.

A Booming Market with Robust Growth

The Indian auto components sector has demonstrated impressive resilience and growth, boasting a compound annual growth rate (CAGR) of 7-8%. By 2030, the market size is expected to soar to approximately Rs. 16.7 lakh crore (US$200 billion), fueled by strong domestic demand and a shifting global supply chain. In FY24 alone, India sold 23.85 million vehicles, a 12.5% year-on-year increase from 21.20 million units in FY23, surpassing Japan to become the third-largest automobile market globally, valued at Rs. 22 lakh crore (US$261.53 billion).

This growth is underpinned by rising indigenisation efforts and the increasing presence of global original equipment manufacturers (OEMs), which are turning India into a preferred hub for designing and manufacturing auto components. Notably, 8% of India’s R&D expenditure is invested in the automotive sector, highlighting its focus on innovation.

Export Potential: A Global Sourcing Hub

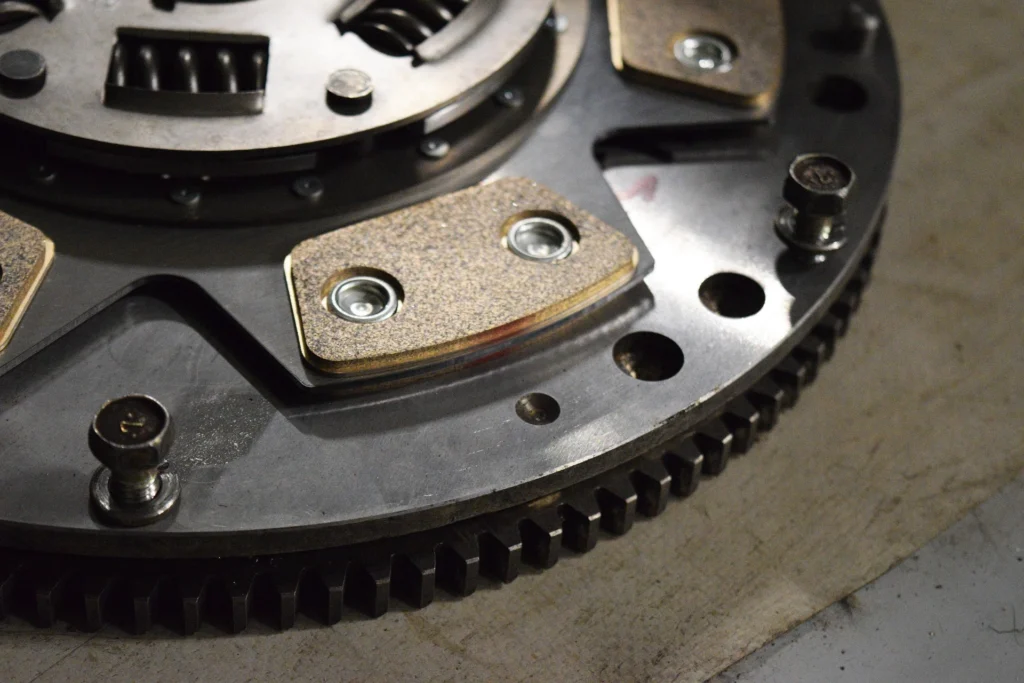

India’s auto components exports are on a steep upward trajectory, growing at a CAGR of 8.75% from $10.83 billion in FY16 to $21.2 billion in FY24. In 2023-24, exports rose by 5.5% to $21.2 billion, with North America (32%), Europe (33%), and Asia (24%) being key markets. By 2030, exports are projected to reach $100 billion, driven by demand for components like engine parts, transmission systems, and suspension systems.

The industry’s competitive advantages—cost-effective manufacturing (10-25% lower than Europe and Latin America), a skilled workforce, and proximity to major markets like ASEAN, Europe, Japan, and Korea—are cementing India’s status as a global outsourcing hub. The ‘China Plus One’ strategy further enhances this position, with companies investing Rs. 58,000 crore (US$7 billion) by FY28 to localize advanced components like electric motors and automatic transmissions.

The Electric Vehicle Revolution

The global shift towards electric vehicles is unlocking massive opportunities for India’s auto components industry. By 2030, the domestic EV battery market could reach $300 billion, with EVs expected to account for 50% of new two-wheeler sales and 70% of three-wheeler sales. In April 2023, GreenCell Mobility announced a Rs. 1,500 crore (US$181.59 million) investment to double its EV bus supply, reflecting the sector’s momentum.

Government initiatives like the Faster Adoption and Manufacturing of Electric Vehicles (FAME) Scheme, extended until March 2024 with an additional Rs. 1,500 crore (US$180.3 million) allocation in January 2024, are accelerating this transition. The Production-Linked Incentive (PLI) scheme, valued at $7.8 billion, is also attracting significant capital expenditure, projected at Rs. 74,850 crore (US$9.58 billion) over the next five years.

Key Growth Drivers

Several factors are propelling the auto components industry forward:

- Domestic Demand: A growing working population and expanding middle class are boosting vehicle ownership.

- Policy Support: Initiatives like 100% FDI under the automatic route, the Bharat New Car Assessment Program (BNCAP), and reduced excise duties on hybrid vehicle parts are fostering growth.

- Competitive Edge: India’s status as the second-largest steel producer globally provides a cost advantage, while investments in R&D are driving technological advancements.

- Automotive Sector Expansion: Vehicle production hit 75.48 million units in FY25 (April-June), reinforcing the demand for components.

Opportunities Across Product Segments

The industry’s potential is balanced across various product types. Engine and exhaust parts, along with transmission and steering components, dominate both domestic and export markets, accounting for nearly 50% of sales. Emerging segments like electronics and electrical equipment are also gaining traction, with the automotive electronics market projected to grow from $10.6 billion to $74.4 billion by 2032, according to ACMA’s September 2023 report.

Companies like Exide, Amara Raja Batteries, and Napino Auto & Electronics are capitalizing on the EV boom by producing lithium-ion batteries, while firms like Steelbird and Vedanta Resources are diversifying into engine oils and advanced alloys.

Major Players and Investments

Leading companies are scaling up capacity and innovation:

- Bosch: Investing Rs. 480 crore (US$58.11 million) in R&D and capex in 2023.

- Tata Motors: Committing $2 billion over four years for new products and platforms.

- Apollo Tyres: Allocating Rs. 1,100 crore (US$133.17 million) in FY24 to expand its EV-friendly offerings.

- Toyota Kirloskar: Investing over Rs. 2,000 crore (US$240 million) in electric components.

Foreign players like Hyundai, Honda, and Volvo are also establishing advanced R&D and manufacturing facilities in India, further boosting the sector’s global footprint.

Contribution to Economy and Employment

The auto components industry contributes 2.3% to India’s GDP and employs over 1.5 million people directly. By 2026, it is expected to account for 5.7% of GDP and create 3.2 million additional jobs, as outlined in the Automotive Mission Plan (2016-26).

Conclusion

India’s auto components industry is at a transformative juncture, driven by robust growth, export opportunities, and the EV revolution. With strong policy backing, competitive advantages, and significant investments, the sector is poised to reach new heights by 2030. As India solidifies its role as a global manufacturing hub, stakeholders—from domestic manufacturers to international OEMs—stand to benefit from this thriving ecosystem.